Overview

Responsibilities

Tasks

-

Read and interpret engineering drawings, blueprints, charts and tables

-

Repair machine tools and parts

-

Set up and adjust production machineries/tools

-

Fit and assemble components and machine parts to close tolerance

-

Maintain, repair and calibrate precision measuring instruments

-

Document and report deviations from specifications and tolerances

-

Verify dimensions of parts machined using precise measuring instruments (e.g., micrometers, calipers)

-

Compute dimensions and tolerances and measure and lay out work pieces

-

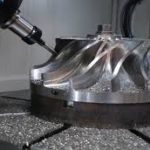

Set up, operate and maintain a variety of conventional and computer numerically controlled (CNC) machine tools

-

Verify dimensions of products for accuracy and conformance to specifications using precision measuring instruments

Experience and specialization

Measuring tools

-

Micrometers

-

Callipers

-

Calibre

-

Gauges

-

Verniers

Equipment and machinery experience

-

Computer numerical control (CNC) machines

-

Drill presses

-

Engine lathes

-

Form cutting machines

-

Milling machines

-

Sawing machine

Specialization or experience

-

Specialized environmental skills and knowledge

Additional information

Transportation/travel information

-

Own transportation

Work conditions and physical capabilities

-

Repetitive tasks

-

Standing for extended periods

-

Attention to detail

-

Overtime required

Weight handling

-

Up to 23 kg (50 lbs)

Personal suitability

-

Accurate

-

Dependability

-

Flexibility

-

Team player

Benefits

Health benefits

-

Dental plan

-

Health care plan

-

Paramedical services coverage

Financial benefits

-

Group insurance benefits

-

Night shift premium

-

Registered Retirement Savings Plan (RRSP)

Other benefits

-

Free parking available

-

Learning/training paid by employer

-

Parking available