WHAT IS CNC MACHINING?

Short for “computer numerical control,” the CNC process runs in contrast to — and thus supersedes— manual control limitations, where live operators are required to prompt and guide the machining tool commands through levers, buttons, and wheels. A CNC machine can look like a regular collection of computer components for the onlooker, but the software programs and consoles used in CNC machining.

Things to Learn About CNC Machining

When a CNC system is activated, the desired cuts are programmed into the software and dictated to the appropriate tools and machinery to perform the dimensional tasks as specified, similar to a robot.

In CNC programming, the code generator within the numerical system often assumes that mechanisms are flawless, despite the possibility of errors, which is greater when a CNC machine is directed to cut simultaneously in more than one direction. A number of inputs known as the part program outline the placement of a tool in a numerical control system.

Programs are inputted via punch cards with a numerical control system. By contrast, small keyboards feed the programs for CNC machines to computers. CNC programming is kept in the memory of a computer. Programmers write and edit the code itself. CNC systems, therefore, offer much more computational capacity. CNC systems are by no means static because newer prompts can be added to pre-existing programs through revised code.

CNC MACHINE PROGRAMMING

In CNC, machines are controlled by numerical control, designating a software program to manipulate an element. Alternatively, the language behind CNC machining is referred to as G-code, and it is written to control a corresponding machine’s different behaviors such as speed, feed rate, and coordination.

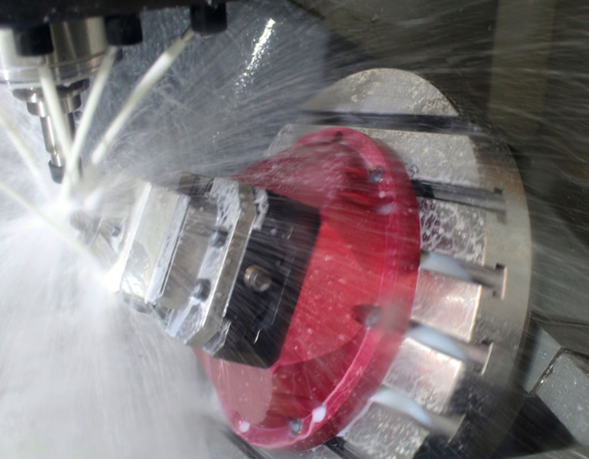

Essentially, CNC machining allows the speed and location of machine tool functions to be pre-programmed and operated through code in routine, predictable cycles, all with no human operators’ involvement. The method has been embraced across all corners of the manufacturing sector as a result of these capabilities and is especially essential in the areas of metal and plastic production.

A 2D or 3D CAD drawing is designed to start with, which is then translated into computer code for executing the CNC system.

Open/Closed-Loop Machine Systems

Using an open loop or closed-loop system, position control is determined. With the former, the signaling runs between the controller and the motor in one direction. The controller is able to receive input with a closed-loop system, which makes it possible to correct errors. Thus, a closed-loop system can correct speed and position irregularities.

CNC Machining is Fully Automated

Any given piece of work may involve a variety of machine tools, such as drills and cutters. Many of today’s computers integrate several different functions into one cell to meet these needs. Instead, an installation may consist of multiple machines and a collection of robotic hands that move parts from one application to another, but operated by the same programs.